If you’ve ever taken on a large-scale lighting project—be it a commercial complex, an industrial facility, or an urban infrastructure project—you already know how many moving pieces are involved. From design to installation, and from procurement to long-term maintenance, each piece of the puzzle needs to be reliable and efficient. But one key player often goes unnoticed: the LED Power Supply factory behind the scenes.

In fact, working with the right LED Power Supply factory can make or break the success of a large lighting project. Why? Because power supplies are the heartbeat of every LED system. Without a steady and reliable current, even the best LED lights can flicker, underperform, or fail prematurely. And in a large-scale project, failure isn’t just inconvenient—it’s costly.

Let’s explore the often-underappreciated but incredibly important role of LED power supply factories, especially when it comes to scaling up lighting systems that need to be powerful, consistent, and long-lasting.

Why Power Supplies Matter in Big Lighting Projects

We often focus on the beauty and efficiency of LED lights themselves—the brightness, color temperature, or energy savings. But none of that would be possible without a power supply converting AC current into usable DC output.

Now, multiply that need by hundreds or even thousands of lighting units. That’s what you’re dealing with in stadiums, office buildings, factories, and large public infrastructure. It’s not just about powering lights—it’s about doing it in a way that guarantees safety, reliability, and efficiency across the entire system.

That’s where the LED Power Supply factory comes in.

1. Precision Engineering at Scale

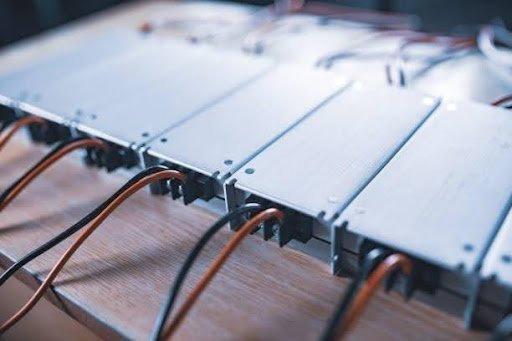

A top-tier LED Power Supply factory isn’t just producing bulk quantities of devices—they’re manufacturing with precision, consistency, and strict quality control. These factories invest in R&D, testing equipment, and automated lines that can handle high volumes without compromising on performance.

Every large-scale lighting project requires consistent voltage and current across many installations. Even a small variance can cause lights to behave unpredictably or overheat. Reliable factories ensure that every power supply produced matches the specifications to the letter, which is essential for system stability.

2. Customization Capabilities for Complex Needs

Large projects often come with unique requirements. Maybe it’s an architectural lighting system that needs dimmable drivers. Maybe it’s an outdoor lighting project that demands waterproof, IP67-rated supplies. Or maybe it’s a smart city initiative requiring networked power supplies with remote control capabilities.

An experienced LED Power Supply factory doesn’t just produce off-the-shelf items. They work with clients to create customized power supplies that meet the exact needs of each project. That flexibility makes them more than just manufacturers—they become problem solvers and collaborators.

3. Reliable Supply Chain and Volume Handling

In big projects, delays can be devastating. If power supplies arrive late—or worse, incomplete or faulty—it can stall everything from installation to inspection. A seasoned LED Power Supply factory has the production capacity, inventory planning, and logistical coordination to handle large orders and ship them on time.

They’ve got experience working with project managers and procurement teams. They know how to manage lead times, quality assurance, and documentation. That level of professionalism brings much-needed peace of mind when the stakes are high.

4. Compliance with Global Safety Standards

Large-scale lighting installations often require adherence to international safety regulations—especially when they’re in airports, hospitals, government buildings, or export projects.

Reliable LED Power Supply factories are already familiar with certifications like CE, UL, FCC, TUV, and RoHS. They design and build products that meet these strict guidelines from the ground up. That means no last-minute compliance headaches for you—and a smoother approval process for your clients.

5. Energy Efficiency and Long-Term Performance

A good factory doesn’t just build for performance today—they build for efficiency over time. When hundreds of power supplies are running 24/7, the energy cost adds up fast.

Modern LED Power Supply factories use high-efficiency components, thermal management systems, and design techniques that reduce power loss. Over the lifespan of the project, this translates to lower operational costs and a smaller environmental footprint.

6. Long-Term Partnerships and After-Sales Support

In large projects, you’re not looking for a one-time supplier—you’re looking for a partner. You need someone who will not only deliver the right units but also help troubleshoot, provide documentation, offer replacements if needed, and support you through future phases of the project.

The best LED Power Supply factories operate with this mindset. They’re in it for the long haul, building trust and offering after-sales services like technical support, repair options, and even on-site consultations when necessary.

Real-World Example: Lighting a Commercial Hub

Let’s take a real-world example. Imagine you’re outfitting a multi-story shopping center with LED lights—ceiling lights, signage, emergency exits, decorative strips, and parking lot illumination. You need power supplies for each of those zones, each with different wattage, waterproofing, and control needs.

A reliable LED Power Supply factory will work with you from planning to post-installation. They’ll recommend the right units, possibly offer custom modifications, help you forecast volumes based on drawings, and ensure that all supplies arrive on-site in sync with your schedule.

And if you hit a snag—say, your outdoor fixtures are overheating due to poor ventilation—they’ll analyze the situation and recommend a different model with better thermal performance. That kind of support is invaluable when you’re managing a massive operation.

FAQs About LED Power Supply Factories

Q1: What’s the difference between a power supply factory and a distributor?

A distributor sells and delivers finished products, often from multiple brands. A factory designs, engineers, and manufactures the power supplies. Working directly with a factory often gives you more customization, better pricing, and deeper technical support.

Q2: Can LED Power Supply factories handle low and high-volume orders?

Yes. While some factories specialize in bulk production, many are equipped to handle both low-volume prototypes and high-volume production, depending on your needs.

Q3: Are all LED Power Supply factories equal in quality?

No. Quality can vary significantly. The best factories follow strict QA protocols, use certified components, and have experience with international projects. Always check for certifications, client references, and sample testing.

Q4: Can a factory help with installation or integration?

While they usually don’t perform installation, top factories provide wiring diagrams, technical data sheets, and consultation to ensure proper integration with your lighting systems.

Q5: How do I find a trustworthy LED Power Supply factory?

Look for one with a strong track record, up-to-date certifications, responsive support, and the ability to customize. Visiting the factory or getting references from previous clients can also be helpful.

Conclusion: Building Brighter Projects Starts at the Factory

The next time you’re planning a large-scale lighting project, don’t just look at the LED fixtures. Zoom out and consider where those power supplies are coming from—because that’s where the real magic starts.A reputable LED Power Supply factory brings more than products to the table. They bring precision, reliability, and partnership. They make sure your lights shine bright, your systems run safely, and your clients are thrilled with the results.When you team up with a factory that understands the stakes, you’re not just buying components—you’re investing in the long-term success of your project.So take the time to choose the right partner. Because in the world of large-scale lighting, power is everything—and it all starts with the right factory.

Also Read: itshifting.com