Have you ever paused and wondered what drives the lights in your bedroom or powers your phone daily? Most haven’t. We insert a device, and it works. However, what happens behind the scenes is an intricate series of machines making it happen, beginning with something referred to as a transformer winding.

What Is Transformer Winding?

Let’s dissect. A transformer is a device that assists in the transfer of electricity from one location to another by converting its voltage. It does this with the purpose that electricity generated at power plants must travel distances to get to residences, schools, hospitals, and factories. However, it can’t do so safely without assistance.

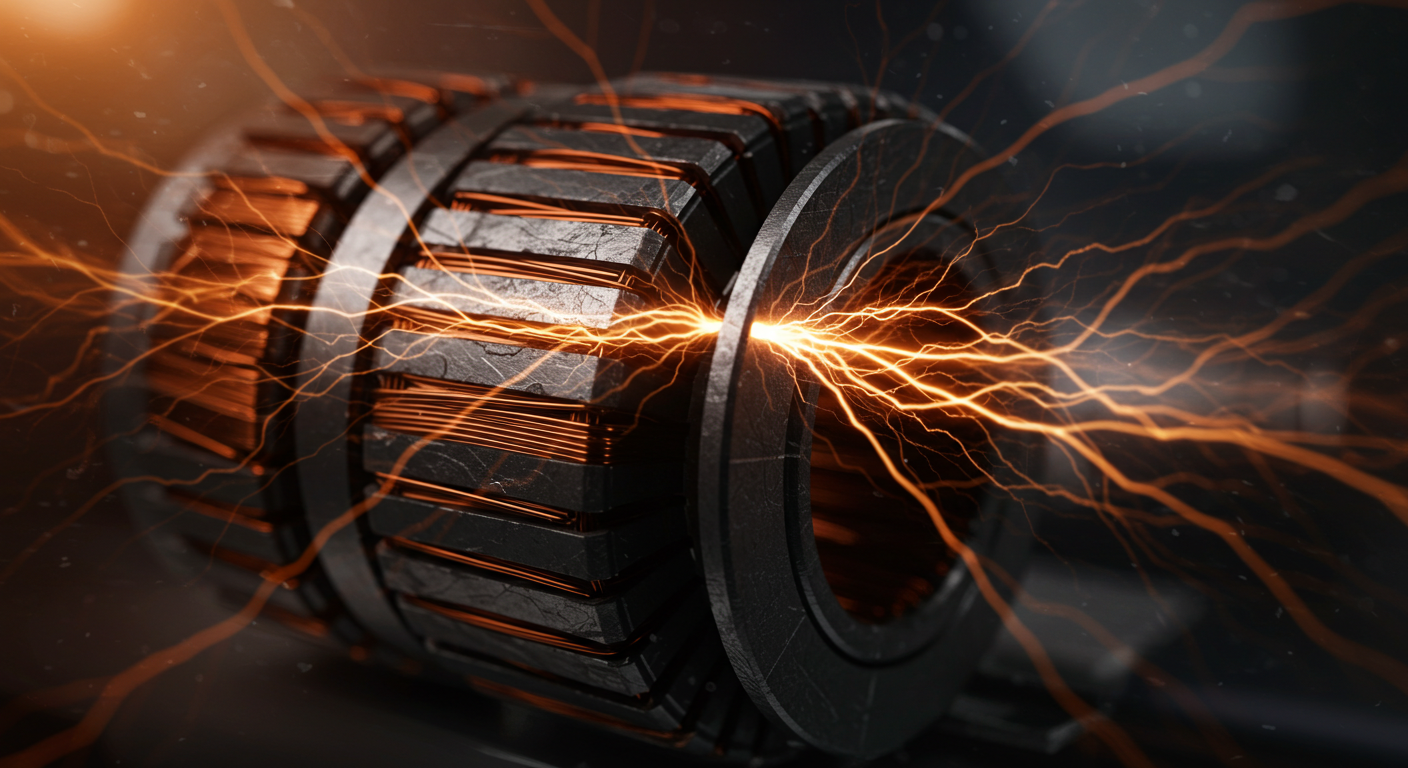

That’s where transformer winding is needed. It is the process of encircling electric current-carrying copper or aluminium wires in a particular manner around a metal core. These wires produce electric currents and generate magnetic fields that assist the transformer in transporting electricity and altering its voltage levels.

You can imagine transformer winding as taking a very, very long string and wrapping it around a metal rod—but the sequence and accuracy make a big difference. If you don’t get it exactly right, the entire transformer may not function at all.

Feel like learning more about the science? Guangri Electronic Machinery Co., Ltd does an excellent job of explaining what transformer winding is and why it makes such a big difference.

Why Should You Care About Transformer Winding?

Even if you’ve never heard of transformer winding until today, it is a big part of your life. Whenever you switch a light on or access Wi-Fi, electricity travels through transformers based on this technology.

The following are just a few examples of where transformer winding makes a significant impact:

- Your Home: Devices such as refrigerators, televisions, and game consoles all require the proper voltage to operate safely.

- Schools: Computers, projectors, and lighting systems rely on a stable electricity supply.

- Hospitals: Medical equipment, such as MRI scanners and X-ray machines, requires particularmor levels of electrical power.

- Factories: Heavy machinery requires heavy-duty transformers to remain operational.

- Planes and Cars: The aerospace and automobile industries utilise small, precise transformers for enhanced safety and performance.

All of this would not be possible without high-quality winding work. That is why precision is everything, and why firms that produce winding machines are so crucial.

How Transformer Windings Are Made

The winding procedure sounds easy—just wrap some wire, correct? But it’s exact and technical.

Every wire has to be wound in a particular sequence and at the appropriate tension. This balances and maximises the magnetic field. If wound improperly, it may lead to overheating, loss of power, or a short circuit.

Guangri Electronic Machinery Co., Ltd produces special machines that do this winding job with perfect precision. Its machines are employed in every corner of the globe to construct transformers for:

- Aerospace systems

- Medical equipment

- Clean storage systems for energy

- Power supplies for industry

Such equipment can deal with sensitive materials and intricate designs, making each transformer safe, efficient, and durable.

If you’re interested in understanding more about such groundbreaking machines and the technology that goes into them, visit the extensive information at grinding.com.

Transformer Winding and the Energy Future

With the development of technology comes the demand for improved, more efficient electricity systems. Consider the emergence of:

- Electric cars (EVs)

- Solar and wind power

- Smart homes and cities

- Battery-operated medical devices

All these depend on efficient transformers that can support special power requirements. For instance, the charging and discharging of solar panel energy require a transformer that is capable of fast charging and discharging power. That would not be feasible without innovative winding technology.

Precision winding enables the creation of smaller, lighter, and more efficient transformers. This means improved energy efficiency, which is beneficial to the environment and saves money. As the demand for clean energy increases, the demand for advanced winding machines will only continue to rise.

New Winding Technology

Guangri and other companies are at the forefront of creating new types of winding machines that are not only faster and more accurate but also better suited to more sophisticated tasks.

Some of the latest innovations in present-day winding machines are:

- Computer accuracy: Machines can replicate precise patterns, minimising human error.

- Auto wire feeding: This maintains even wire tension and avoids damage.

- Multilayer winding assistance: This enables transformers to be more compact with higher power capacity.

- Digital observation: Operators can observe the entire process on a monitor and make real-time adjustments.

These advancements enable manufacturers to meet the growing demand for high-quality transformers across various industries. It’s not merely a matter of making it faster—it’s about making it brighter and safer.

You may never notice transformer winding at work on any given day, but it’s toiling away behind the scenes to keep your world spinning. From powering a hospital to charging your phone, this technology connects with nearly every aspect of modern life.

As the world shifts toward clean energy and intelligent technology, transformer winding will become increasingly crucial. That’s why businesses like Guangri Electronic Machinery Co., Ltd are making an investment in the future—constructing machines that drive progress, winding by winding.

For more on transformer winding and how it drives industries worldwide, go to grwinding.com.