Today’s electronics world moves so quickly that every new gadget demands smaller parts, faster speeds, and lower costs. Meeting that challenge on a large scale depends on dependable manufacturing. Nestled in that system, though often ignored, are precision stamped parts. These tiny metal pieces are made with such tight tolerances and repeatability that they quietly hold together the performance and future of every device.

Behind each punch-out stands precision CNC machining companies that add vital know-how in design, tooling, and assembly. In the lines that follow, we’ll show how stamped parts fuel electronics breakthroughs and why choosing a skilled CNC partner can launch tomorrow’s technology.

The Critical Role of Stamped Parts in Electronic Assemblies

Every gadget-from everyday smartphones to high-end industrial sensors-packs dozens of metal components that slide into tiny slots, cope with heat or shock, and shield fragile circuits from stray signals.

Precision stamped parts show up all over electronics:

- Shielding covers

- Battery contacts

- Connector terminals

- Heat-sink fins

- Frame supports

- EMI/RFI filters

Using a stamping press lets factories crank out these metal bits by the thousands while keeping dimensions tight. Whether it is a mini clip inside a health-tracking watch or a sturdy bracket in a cell tower, stamped parts keep electronics lean, accurate, and cheap.

Design Considerations: Tolerances, Complexity, and Speed

When engineers sketch a new gadget, they do not just chase better specs. They also ask whether the part can be stamped, because speed and cost matter as much as performance.

Tolerances That Enable Functionality

Most circuit boards leave little room for slop. A crooked connector or flimsy bracket can ruin a device. Metal formed in a well-set press can hold tolerances within a few microns, so parts fit together the first time. Tight tolerances also boost grounding, cooling, and shielding against stray signals.

Complex Geometries for Advanced Performance

Modern dies add ribs, bends, and embossed touches in one stroke. Those extra shapes save space and weight while letting tiny parts do multiple jobs. As phones, laptops, and sensors shrink, that level of complexity is no longer optional-it is critical.

Shorter Design-to-Market Cycles

Stamping shines when jobs need speed. Pair that with die work and tooling from top CNC shops, and you get fast prototypes, quicker shelves, and a real edge where ideas never sit still.

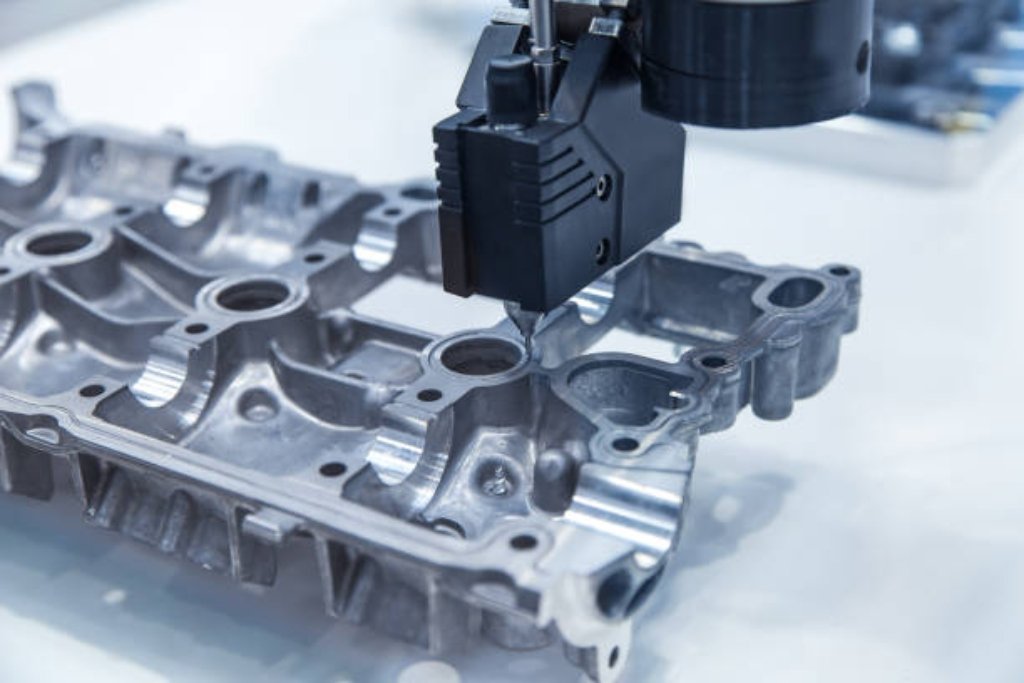

How CNC Shops Fuel Stamping Innovation

Though stamping stands on its own, it leans hard on CNC work for dies, cleanup, and fit-up. Skilled CNC shops turn CAD sketches into working tools and make sure each stamped piece keeps pace with changing standards.

Die Design and Fabrication

The die-and-blank holder-set is what shapes every part in stamping. If the die is off, parts wobble, cycles slow, and costs climb. CNC lathes and mills cut the profiles, hold tight tolerances, and leave finishes so smooth that dies last longer and every piece looks right.

Hybrid Part Manufacturing

Sometimes a stamped blank still needs a final touch or two. Quick CNC slots, holes, or threads add those features-and only those-without starting a whole new run. Mixing the two keeps tools busy, cuts waste, and gives designers way more room to think.

Surface Finishing and Quality Control

Electronics often need extra care on their surfaces, so you’ll see operations like plating, anodizing, or special coatings. Modern CNC lines mix these finishes with tight quality checks, keeping each batch uniform where conductivity or insulation is on the line.

Prototype Validation

Before a full stamping run, designers may CNC-machine a quick prototype. Doing so speeds development, spots problems early, and cuts wasted time and money when moving to larger volumes.

Applications of Precision Stamped Parts in Electronics

The electronics industry always demands parts that are exact, dependable, and easy to scale. Below are a few places where precision-stamped elements and skilled CNC shops push performance forward:

Consumer Electronics

Inside phones, tablets, and wearables you will find stamped battery clips, SIM trays, and heat spreaders. Each piece must be razor-thin, super tough, and made by the millions without defects.

Automotive Electronics

EV control boxes, ADAS sensors, and infotainment displays depend on stamped brackets, shields, and ground tabs. Parts made to the tightest tolerances keep these systems working through heat, vibration, and voltage spikes.

Telecommunications

Inside routers, satellites, and data hubs, precisely stamped RF shields and connectors do hard, unseen work. Their stable sizes and strong electrical paths steady signals and cut down stray electromagnetic noise.

Industrial and IoT Devices

Smart sensors and PLCs often hide tiny stamped brackets and links inside their shells. Stamping lets designers shrink parts, while quick CNC tweaks let engineers adapt layouts on-site.

Medical Electronics

Defibrillators, patient monitors, and lab analyzers call for stamped bits made from biocompatible metal, all cut to micrometer precision. Fast CNC work then fine-tunes edges and holes for a perfect fit.

What to Look for in a Machining Partner

To get the most from stamped parts, electronics makers need suppliers who deliver tooling and finish work on time, every time, and with fresh ideas.

Keep these traits in mind as you vet precision CNC shops:

- Experience in Electronics Tooling: The team should know how each metal behaves, spot early tool wear, and measure how tight tolerances affect PCB and case assembly.

- Advanced Equipment: New-model CNC lathes and mills with built-in sensors run jobs repeatedly and handle secondary steps without hand-offs.

- Cleanroom and ESD Compliance: Sensitive parts need spotless, static-free air, so choose a partner committed to ESD rules and contamination-free processing.

- Rapid Turnaround: Because the tech world moves at breakneck speed, choose a supplier that can send you prototypes and small runs in days, not weeks.

- Scalability Support: Make sure your partner can shift smoothly from first samples to high-volume tools and still back you up when your design gets an update.

The Future of Electronics: Driving Innovation Through Stamping and Machining Synergy

As gadgets shrink, run faster, and pack in more features, razor-sharp precision now sets apart the makers that win.

Watch for these trends:

- Flexible Stamped Electronics: Growing bendable circuits will need stamping that works with new conductive films and constantly changing shapes.

- Thermal-Structural Integration: Parts that cool and stiffen at the same time demand a tight stamp-and-machine team that never misses a micron.

- Smart Tooling: AI watches CNC and press lines, flags tool wear early, tunes settings on the fly, and cuts waste before it piles up.

- Global Compliance: With rules getting tougher everywhere, suppliers must ship parts that are traceable and certified in every market you enter.

Conclusion

From the first sketch to the final test, precision-stamped parts lie at the heart of today’s smarter, quicker, and smaller electronics. Their true power kicks in only after design, tooling, and assembly work together like clock gear.

Precision CNC machining shops link a sketch on paper with the finished part, guaranteeing every stamped component is made with top-notch accuracy, repeatability, and the ability to scale. For B2B electronics makers, building solid ties with these machining pros isn-t just cheaper; it-s the edge they need to outpace rivals and keep pushing new ideas.