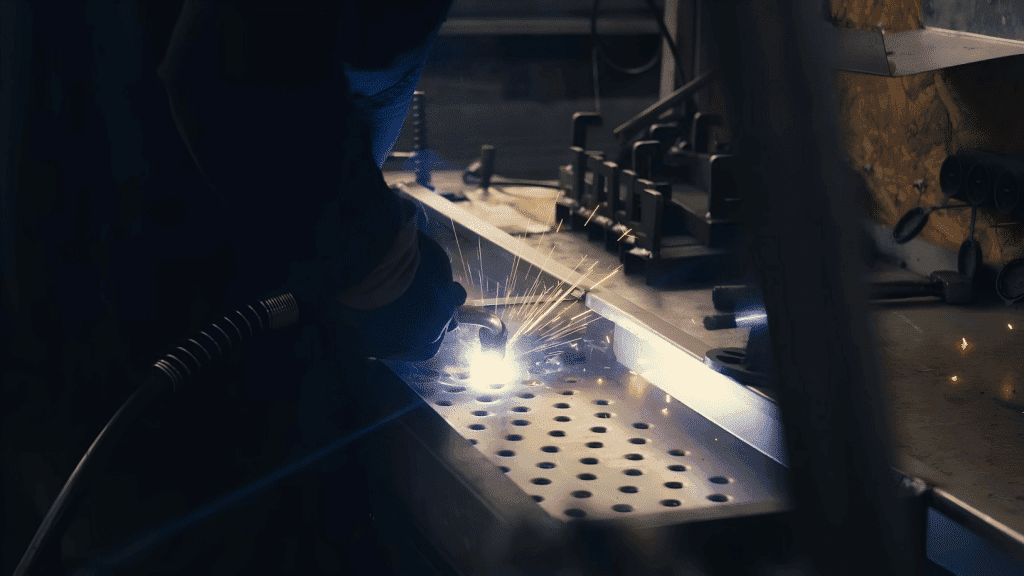

In industrial manufacturing, efficiency and consistency are everything. A single weld misalignment in mass production can translate into costly rework, downtime, or even product recalls. This is where the welding fixture machine factory comes in—serving as the critical link between product design and large-scale production.

These specialized factories transform CAD drawings and part requirements into precision-engineered fixtures that hold, align, and support components during welding. Their role ensures that every weld meets specifications, minimizes defects, and supports high-speed, automated production lines. In short, they bridge the gap between design vision and shop floor reality.

Early Stage: Specification & Requirements Gathering

Understanding Weldment & Assembly Needs

Every fixture begins with understanding the weldment: geometry, joint type, tolerances, and material behavior. Factors like heat input, distortion risks, and clamping constraints must be carefully considered.

Collaboration with Engineering Teams

Factories work closely with designers, exchanging CAD models and drawings. The goal is clear: define fixture parameters that guarantee repeatability, accessibility, and cycle-time efficiency.

Balancing Cost & ROI

The complexity of a fixture depends on production volume. For high-volume runs, investing in sophisticated tooling pays off through reduced scrap, faster setups, and long-term consistency.

Fixture Design & Engineering

Conceptual Layout

The design phase defines locator points, clamping strategies, and supports. Thermal expansion, deflection, and ergonomics are all factored into the initial concept.

Digital Modeling & Simulation

Advanced 3D CAD and finite element analysis allow engineers to test rigidity, simulate welding stresses, and evaluate operator workflows virtually—before a prototype is built.

Manufacturability & Assembly

Designs are refined to ensure fixture parts can be easily produced, assembled, and maintained. Standardized components and modular designs improve usability and lower costs.

Prototyping & Validation

Trial fixtures are often fabricated and tested with real welds. These prototypes reveal issues like distortion or accessibility challenges, which can be refined before full-scale manufacturing.

Manufacturing of Fixtures in the Factory

Material Selection & Production

From durable steels to modular aluminum elements, material choice depends on strength, thermal resistance, and expected usage. Processes like CNC machining, EDM, grinding, and welding produce high-precision parts. Laser metal cutting is also widely used, offering clean edges and minimal material waste, which is essential for precision-driven industries.

Sub-assembly & Quality Control

Fixture components are carefully aligned and tested for planarity, locator accuracy, and clamp performance. This ensures interchangeability and precision before final delivery.

Automation & Sensor Integration

Factories often incorporate pneumatic or hydraulic clamping, servo actuators, and even sensor systems for monitoring displacement or force.

Scalability Through Modular Manufacturing

Some factories build modular kits, allowing manufacturers to adapt a single fixture across multiple part families, reducing lead time and tooling costs.

Testing, Commissioning & Iteration

Factory Acceptance Testing

Fixtures are tested for repeatability, clamp strength, and fit. Simulated welding cycles confirm they withstand heat and distortion.

Field Testing

Once deployed, fixtures are integrated into welding cells and tested in real-world conditions. Observations lead to refinements in design or component placement.

Iterative Refinement

Feedback loops are crucial. Adjustments—like adding supports or reconfiguring clamp positions—improve usability and extend fixture life.

Deployment & Lifecycle Support

Installation & Integration

Fixtures are mounted into robotic or manual welding stations and calibrated to match torch paths and operator workflows.

Maintenance & Repair

Wear parts, locator pins, and clamps require periodic maintenance. Factories provide hardened surfaces, replaceable parts, and calibration guides to extend service life.

Upgrades & Reconfiguration

As production evolves, fixtures can be retrofitted with sensors or adapted for new part variants, ensuring continued relevance.

Documentation & Spare Parts

Every fixture is delivered with documentation, bills of materials, and maintenance guides, enabling efficient repair and inventory planning.

Business & Operational Role of a Fixture Machine Factory

Turnkey Delivery

A welding fixture machine factory provides end-to-end solutions: from design through build and testing, ensuring manufacturers receive ready-to-integrate tooling.

Scalability & Customization

Factories can serve both small custom projects and large-scale production. Modular designs make this scalability cost-effective.

Competitive Edge

Fast quoting, short lead times, and robust after-sales support differentiate fixture suppliers. Precision and durability further enhance customer trust.

Partnerships with Welding Machine Providers

Close collaboration with welding system providers ensures fixtures align perfectly with robotic, laser, or manual welding equipment. This integration minimizes compatibility issues.

How a Welding Fixture Machine Factory Model Aligns with Denaliweld Strategies

Denaliweld embraces a modular and precision-driven fixture philosophy. By partnering with a welding fixture machine factory approach, they ensure:

- Fixtures that integrate seamlessly with its welding systems.

- Precision alignment that guarantees consistent weld quality.

- Modular fixture designs that adapt to evolving production demands.

- Lifecycle support with spare parts and rapid turnaround to keep production moving.

This alignment delivers practical efficiency gains for manufacturers looking to combine advanced welding systems with dependable fixturing solutions.

Conclusion

A welding fixture machine factory is more than just a supplier—it’s the cornerstone of modern manufacturing consistency. From design and simulation to production and lifecycle support, these factories ensure fixtures are reliable, durable, and efficient.

As automation and Industry 4.0 reshape production, the need for precise, adaptable fixtures only grows. By choosing fixture partners that emphasize modularity, innovation, and integration you can bridge the gap between design and high-quality mass production, ensuring efficiency and competitive advantage.