Moisture has always been the biggest enemy of 3D printing. In certain areas of the world, especially the lowlands and tropical ones, humidity can reach as much as 95% which can affect your final results.

From bubbling on the surface, clogged nozzles, to brittle parts, the wet filament is often printed into waste. That’s why filament dryers, silica packs, sealed storage, and other homemade solutions are used by many makers to protect their filaments and investments.

But what if we solve the issue in the first place? Science has made a lot of advancements over the past couple of years, and now, we have moisture-proof filaments that are made from materials perfect for resisting water absorption at a much deeper level.

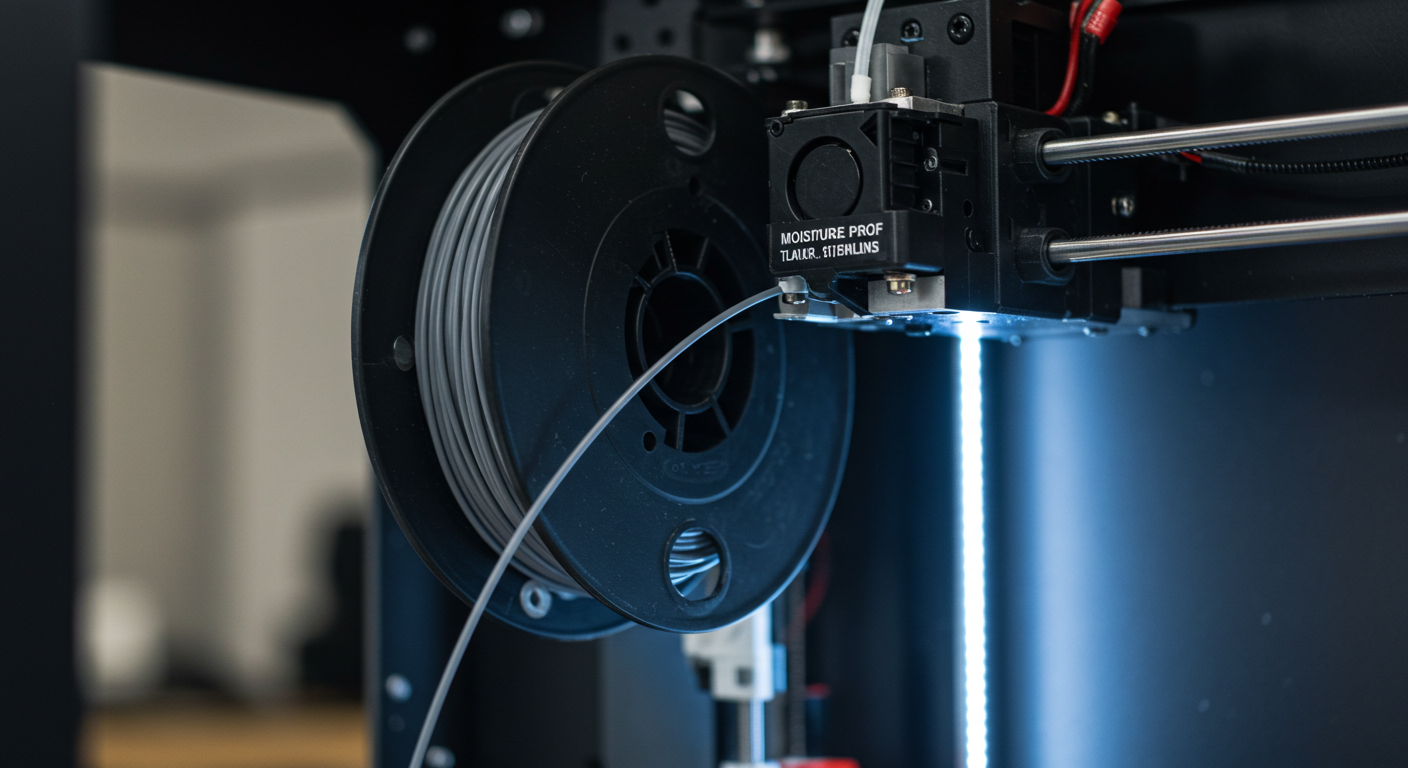

While they are not here to replace the current filaments, and you still need a filament dryer like the Chitu System FilaPartner E1 to get rid of the moisture, moisture-free filaments are a step in the right direction. So, let’s uncover the truth behind moisture-free filaments.

Why Does Moisture Create So Many Issues?

To understand the severity of moisture damage to the filament, we must know some key things and really find out why hygroscopic materials create so many issues.

- Water Absorption: Most filaments, like nylon, PVA, and PETG, will pull water even from the air. This means that if you have a humid environment, meaning the water particles are in the air, even a few hours in a humid room will impact the printability.

- Bubble Formation: During the 3D printing process, the absorbed water in the 3D printer vaporizes into steam and manifests in the form of bubbles, rough surfaces, or even weaker prints.

- Nozzle Stress: Once the stream expands into the nozzle, the increased pressure can cause clogging or even block the whole nozzle.

- Degradation: Water damage can quickly weaken the filament, reducing the 3D printer object even if it’s printed properly.

Introducing Moisture-Proof Filaments

Moisture-free filaments incorporate polymers that are modified to reduce the hygroscopic nature, and many manufacturers are slowly tapping into this side as well. Moisture-proof filaments can be achieved through:

- Using hydrophobic polymers like polyolefins and more.

- Blending in nano-additives or coatings that avoid or repel water.

- Adding moisture-resistant barriers at the filament level to make it absorb less water.

So, instead of water absorbing quickly, these filaments would remain stable even in high-humidity environments. For 3D printing businesses that live in humid areas, moisture-free filaments are already working, and they can easily print without having to continuously dry or pre-dry the filament using a dryer.

Current Moisture-Free Filaments On The Market

The current market isn’t full of moisture-free filaments, but there are a few options you can consider. One of the most common types is the hydrophobic nylons. These are basically certain nylon blends that claim that they have lower moisture absorption by up to 70%, which is such a huge win compared to the standard grades.

Another popular form is the PLA variants with coatings. We already know that PLA comes in other forms, like Silk PLA. However, there are new coated PLA filaments that have improved shelf life, especially in humid climates. This makes them perfect for people who print once in every blue moon.

Other than these, there are some fluoropolymers and nano-silica blends that are still in research & development. And according to the teams, they will provide even stronger moisture resistance in the next few years.

For now, the market of moisture-free filaments isn’t really flourishing, but we can expect it to grow very soon.

The Benefits of Moisture-Free Filaments

Once widely available, these are some of the benefits we could expect from moisture-proof filaments:

- Revolutionizing Drying Equipment:

Right now, filament dryers are quite important, but in the coming years, they might shift towards just storage boxes or be changed into something entirely different since there will be less of a need for them.

- Consistent Output:

Without any moisture or humidity fluctuations, the print quality will improve. Moisture-proof materials will have consistent results regardless of the environment or the place you’re printing from.

- Beginner-Friendly Experience:

One of the things that discourages new users from 3D printing is that their results almost never come out consistently. This is something that will change with moisture-proof filaments because now, anyone would be able to print without much trouble.

- Reliability:

In professional environments, humidity still exists, and it can really cause a lot of destruction if not monitored properly. Materials that won’t require constant drying will improve the overall workflow and help businesses produce proper and high-quality products.

Lastly, in some coastal and tropical regions, humidity is almost unavoidable. Even putting a filament out of drying for a few moments could mean that it would absorb water. Therefore, in those regions, a moisture-proof filament would make printing significantly easier.

The Current Challenges

Currently, there are some challenges that this niche industry is facing. For example, the hydrophobic filaments currently available on the market come at a premium price tag. This makes them less attractive for both hobbyists and beginners.

Until the cost drops, Drypers would remain at a cheaper price and a much cheaper solution. Next, moisture-proof variations only exist for a few filaments, like Nylon, for now. Other standard filaments like PLA, ABS, and PETG are still dominating the market.

Final Verdict

Overall, moisture-proof filaments do seem like the future of 3D printing, but there’s a lot of innovation that must be done. In the coming years, trends are most likely to shift, and moisture-proof could become the next normal for 3D printing.

If you want to get top-notch 3D printing accessories, check out Chitu Systems today.