In the evolving landscape of oil and gas extraction, ensuring the integrity and productivity of oil wells after casing is more critical than ever. Cased hole logging has become a foundational practice, providing operators with vital diagnostics and performance data without disturbing the established casing. By leveraging a range of cased hole services, oilfield professionals gain detailed insights that inform better operational decisions, maximize recovery, and prevent costly issues.

Unlike open-hole logging, which is performed before the casing is set, cased hole logging techniques are carried out later in the well’s life cycle. This enables ongoing monitoring, maintenance, and optimization of producing wells, safeguarding investments, and enhancing field longevity.

With the mounting demand for higher efficiency and reduced risk, advanced cased hole logging solutions offer the industry a pathway to safer, more productive, and more economical operations. Techniques and technology in this domain have evolved significantly, integrating new tools and approaches to characterize subsurface conditions and wellbore health better. Importantly, the synthesized data fuels decisions that can increase production, mitigate hazards, and optimize interventions for a wide variety of well types and field settings.

Essential Tools in Cased Hole Logging

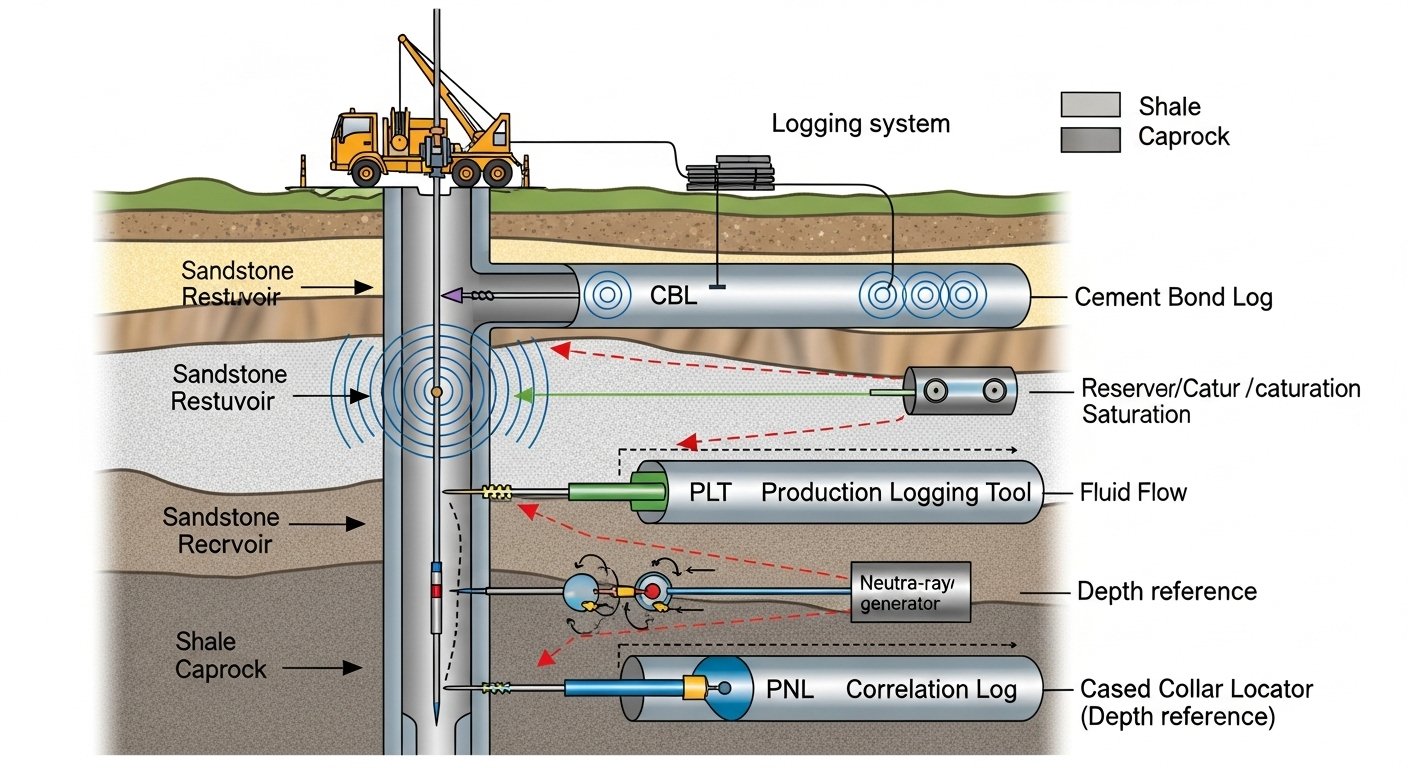

Cased-hole logging utilizes a suite of specialized instruments to provide a clear picture of wellbore integrity, fluid movement, and production dynamics. Among the most widely used tools are:

- Multi-Finger Caliper (MFC): By using multiple high-resolution fingers, the MFC precisely measures the internal diameter and geometry of the well casing and tubing. This enables operators to detect corrosion, mechanical damage, deformation, and the buildup of scale, all of which are vital for assessing long-term well health and determining when to intervene. Accurate caliper logs are a crucial aspect of forecasting well maintenance and ensuring production remains on track.

- Pulsed Neutron Tool (PNT): Leveraging fast neutron pulses, PNTs help evaluate porosity, quantify water saturation, and distinguish hydrocarbon zones behind casing. These tools are non-intrusive and can pinpoint bypassed pay or water breakthrough, key to optimizing hydrocarbon recovery without resorting to costly workovers or sidetracking.

Advancements in Cased Hole Logging Technologies

Today’s cased-hole logging technologies are characterized by their sophistication and reliability. Innovations such as high-resolution imaging and digital sensors offer significantly deeper analytical capabilities than traditional logging devices. Tools that generate three-dimensional images of the casing with excellent fidelity enable rapid and accurate assessments of damage, leaks, or subsurface migration pathways.

Many modern systems also utilize advanced telemetry, fiber optics, and artificial intelligence, empowering teams to automate data processing and flag problems before they escalate. These advancements have not only increased the quality of information but also streamlined the logging process and boosted safety for field personnel.

Integrating Data for Enhanced Decision-Making

The true benefit of cased hole logging is realized when vast volumes of collected data are transformed into actionable insights. State-of-the-art software platforms can integrate, interpret, and visualize this data, driving a holistic understanding of well performance and potential interventions.

Through early identification of high-water-producing intervals, operators can isolate problem zones, initiate treatments, and recalibrate artificial lift systems. Such targeted decisions help extend the lifespan of wells, improve recovery rates, and control operational costs, adding tremendous value throughout a well’s productive life.

Ensuring Well Integrity and Safety

Regular monitoring through cased hole logging is vital to safeguard people, capital, and the environment. Key tools, such as Cement Bond Logs (CBL), not only ensure sound cementation between the casing and the wellbore but also prevent fluid migration and cross-flow between geological layers. This is crucial for maintaining regulatory compliance and reducing the risk of blowouts or unwanted water/gas production. The systematic use of integrity tools enables operators to address problems proactively, preventing minor defects from threatening production or becoming costly remediation projects, making it an indispensable practice for responsible reservoir management.

Challenges and Considerations

Cased hole logging is not without its challenges. The presence of a steel casing can complicate data collection, potentially obscuring formation signals or introducing artifacts. Highly specialized calibration, robust interpretation algorithms, and experienced personnel are required to disentangle these effects and produce accurate evaluations. Costs associated with advanced logging solutions, data handling, and software must also be weighed against the operational advantages. As data volumes grow, oilfield teams increasingly rely on collaboration and digital innovation to extract the highest value from their cased hole logging investments.

Conclusion

Cased hole logging is a cornerstone of modern oilfield management, providing critical diagnostics for well integrity, production optimization, and risk mitigation. By capitalizing on cutting-edge tools and integrated data analysis, operators can make informed decisions, maximize output, and enhance the longevity of their most valuable assets in a highly competitive sector.