By mid-2025, some automotive OEMs report waiting more than 50 weeks for critical ICs—longer than their entire vehicle development cycles. At the same time, global trade in counterfeit electronics is projected to exceed $75 billion, flooding the market with components that look real but fail in the field. For engineers and procurement managers alike, the question is no longer “what’s the unit cost?”—it’s “can I trust what’s on my board?”

This is why finding a truly reliable partner matters more than ever. For procurement managers, the wrong choice means explaining delays in boardrooms and scrambling for replacements. For engineers, it means prototypes that never make it past the lab. A supplier today is not just a logistics provider—they are the gatekeeper of authenticity, predictability, and compliance in an increasingly volatile world.

For businesses looking to cut through uncertainty, you can click here to connect with DiGi-Electronics, an authorized global electronic components distributor with 100% genuine parts, ISO-certified processes, and proven supply reliability. In this guide, we’ll show you which risks to watch in 2025, how to evaluate potential partners, and which traits separate reliable suppliers from risky ones.

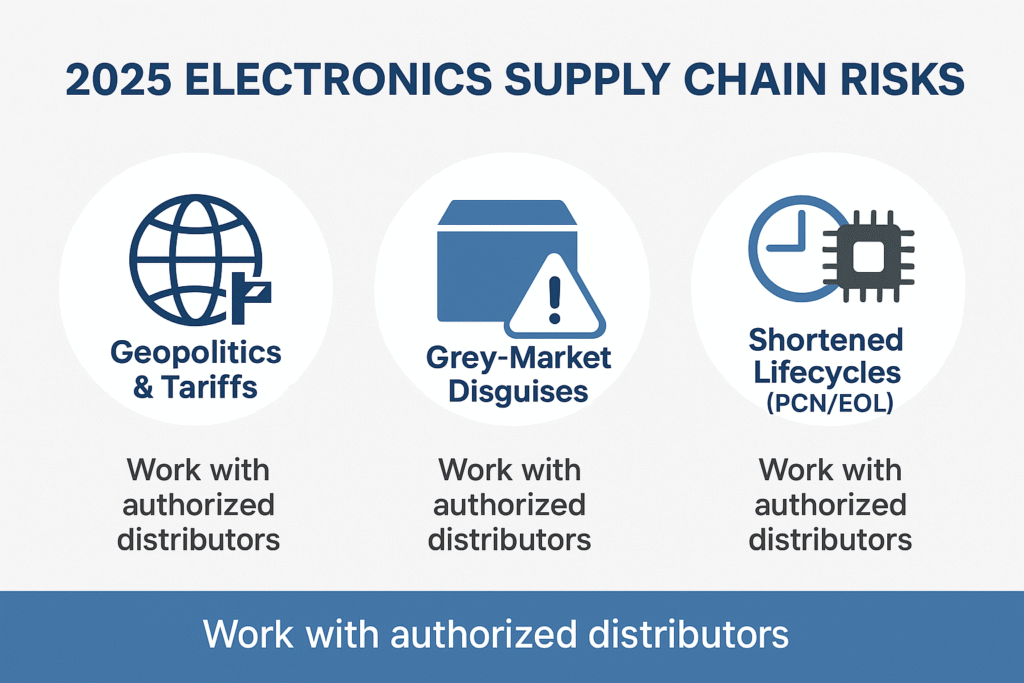

The 2025 Supply Chain Reality: New Pressures, New Risks

Even after the peak of the global chip shortage has passed, 2025 shows that the electronics supply chain is anything but stable. Instead of easing, the risks have shifted into new forms that directly affect both engineering schedules and procurement strategies.

Geopolitics and Tariffs

Trade restrictions and shifting regional alliances continue to shape component availability. A design team may finalize its BOM in Asia, only to find that a critical part is delayed by customs disputes in Europe. Tariffs and export controls add hidden costs and force sourcing teams to juggle multiple vendors across regions instead of relying on one predictable pipeline.

Grey-Market Disguises

Counterfeiters have become far more sophisticated. Today’s grey-market suppliers repackage used parts, produce near-perfect documentation, and even replicate Certificates of Conformance. At first glance, these components look legitimate—until they fail during validation or, worse, in the field. Identifying authenticity now requires not only testing but also choosing suppliers with direct manufacturer authorization.

Shortened Product Lifecycles

End-of-Life (EOL) and Product Change Notices (PCNs) now come faster than many design teams can adapt. A microcontroller selected in 2023 may already be on the way out in 2025. Without proactive lifecycle alerts, companies risk redesigns, unexpected costs, and major delays.

The Takeaway: The supply chain risks of 2025 are not just about shortages—they are about unpredictability. That is why many engineering and procurement teams click here to work with www.digi-electronics.com, a distributor that guarantees traceability, holds its own inventory, and serves customers in over 200 countries.

What Reliable Suppliers Look Like in 2025

With risks multiplying, the difference between a reliable supplier and a risky one is no longer subtle. In 2025, dependable electronic components suppliers consistently demonstrate four key traits.

Traceability and Certificates

Every shipment should come with Certificates of Conformance (CoC) and full traceability back to the original manufacturer. In an era where counterfeiters can fake labels and packaging, verified chain-of-custody is the only safeguard.

Inventory Transparency and Depth

A strong supplier provides real-time inventory visibility, maintains meaningful in-house stock, and offers flexible order sizes—including no minimum order requirements. This combination allows both prototyping and production runs to proceed without delay.

Compliance and Certifications

From ISO 9001 quality management to ISO 14001 and ISO 45001 certifications—along with RoHS and ESD compliance—a trustworthy supplier shows commitment to international standards. These aren’t just checkboxes; they directly affect whether your boards pass audits, environmental tests, and long-term reliability checks.

Global Logistics and RMA Support

Global sourcing brings global risk. A reliable partner can navigate tariffs, customs delays, and shipping bottlenecks, while also offering warranty coverage and responsive RMA processes. This ensures problems don’t snowball into costly downtime.

The Takeaway: In 2025, a reliable supplier is not the one with the cheapest quote—it’s the one with transparent inventory, clear documentation, and a proven ability to keep projects moving across borders.

How to Evaluate: A Practical Framework

Knowing the traits is important, but putting them into practice requires a repeatable framework. In 2025, this five-step process helps both engineers and procurement teams evaluate potential suppliers with confidence.

- Verify Authorization and OEM Relationships

Check if the supplier is listed as an official partner. Authorized distributors guarantee authenticity and provide warranty-backed inventory directly from manufacturers. - Demand Certificates and Testing Records

Every batch should come with CoCs, and for high-value parts, independent testing records when available. This ensures compliance and mitigates counterfeit risks. - Compare Inventory Policies

Look beyond “in stock.” Reliable partners support partial shipments, low MOQs for prototypes, and reserve stock for scaling projects. - Assess After-Sales and RMA Responsiveness

Warranty coverage and clear RMA processes show whether a supplier will stand behind their products—or leave you to absorb the risk. - Use a Supplier Scorecard

Score candidates on authorization, traceability, logistics, and after-sales support. This makes decisions objective, not just about price.

The Takeaway: A framework reduces subjectivity. It ensures supplier evaluation is not guesswork but a structured decision-making process that can withstand executive scrutiny.

Grey-Market in 2025: Why the Risks Are Greater

In earlier years, the difference between authorized and grey-market suppliers was straightforward. In 2025, that line has blurred—and the stakes have risen.

- Counterfeiters Have Evolved → Repurposed parts now come with convincing packaging and even fake CoCs. Detection often happens only after costly failures.

- Cross-Border Complexity → Multi-jurisdictional shipping creates opportunities for label swaps and paperwork manipulation, making authenticity harder to trace.

- Escalating Costs → A bargain batch that fails in the field can trigger recalls, penalties, and reputational damage. For industries like automotive or aerospace, the costs can reach millions.

The Takeaway: Grey-market suppliers in 2025 are more sophisticated than ever, making authorized distribution not just safer—but essential for long-term resilience.

Case Snapshots: Lessons from Three Scales

Startup: Innovation Delayed

A fast-growing IoT startup sourced microcontrollers from a grey-market vendor. The parts passed inspection but failed validation, delaying launch by three months—long enough for a competitor to seize market share.

SMB: Avoiding the Lifecycle Trap

A mid-sized automation firm relied on a power IC that went EOL. Without PCN alerts, they discovered too late and had to redesign. Switching to an authorized distributor provided early notifications and pin-compatible alternatives.

Enterprise: Scaling with Confidence

A multinational automotive OEM faced growing EV demand. By working with an authorized global distributor, they secured allocation, real-time inventory visibility, and consistent delivery across multiple plants.

The Takeaway: Whether startup, SMB, or enterprise, the principle is the same: supplier choice directly shapes outcomes.

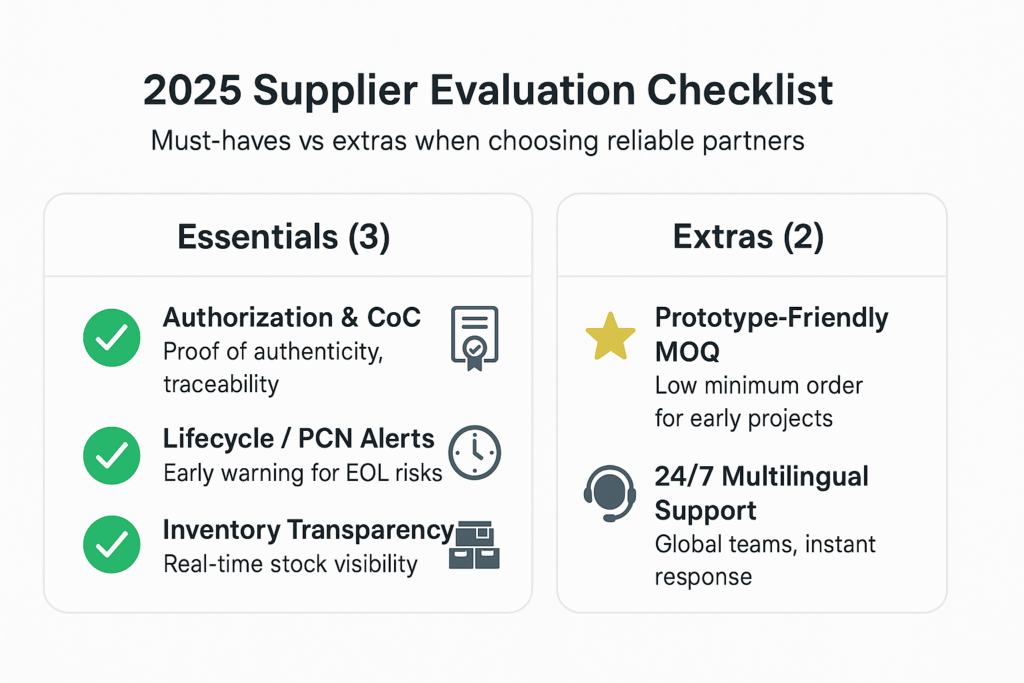

2025 Supplier Checklist: Essentials + Extras

Essentials (3)

- Authorization & CoC → Tie every shipment to verified OEM records.

- Lifecycle / PCN Alerts → Stay ahead of redesign risks.

- Inventory Transparency → Real-time stock visibility prevents surprises.

Extras (2)

- Prototype-Friendly MOQ → Support for innovation without overcommitment.

- 24/7 Multilingual Support → Global teams need around-the-clock coverage.

The Takeaway: Three essentials protect every project; the extras distinguish great suppliers from merely adequate ones.

Conclusion: Predictability Is the New Competitive Edge

In 2025, electronics sourcing is no longer about the lowest unit cost—it’s about predictability. Lead times, authenticity, and lifecycle visibility define whether projects succeed or stall.

The lessons are clear:

- Authorization is non-negotiable → the safeguard against counterfeit risk.

- Transparency beats uncertainty → inventory and lifecycle visibility keep designs on schedule.

- Support defines resilience → warranty and RMA protection keep costs under control.

For startups, SMBs, and enterprises alike, choosing the right supplier is not tactical—it is strategic. Between 2025 and 2030, the companies that thrive will be those that build predictable, resilient supply chains. The next step is clear: review your supplier list now and cut ties with partners who cannot provide transparency, authorization, and long-term reliability.